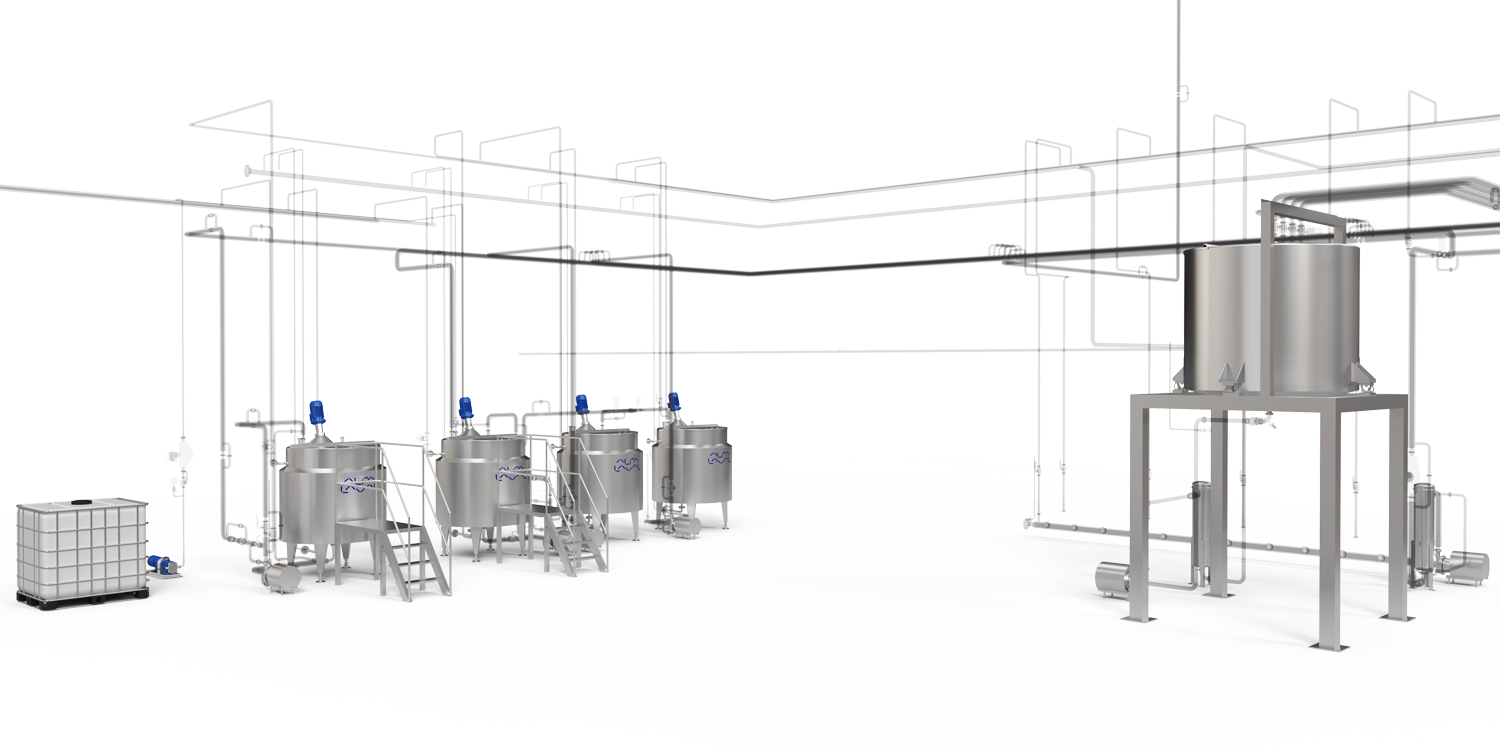

Iyo nzira yekugadzira margarine ine zvikamu zvishanu: chikamu chemafuta chine emulsifier kugadzirira, chikamu chemvura, kugadzirira emulsion, pasteurization, crystallization uye kurongedza.Chero kugadzirwa kwakawandisa kunodzoserwa kuburikidza neinoenderera rework unit kune emulsion tank.

Oiri chikamu uye emulsifier kugadzirira mukugadzirwa kwemajarini

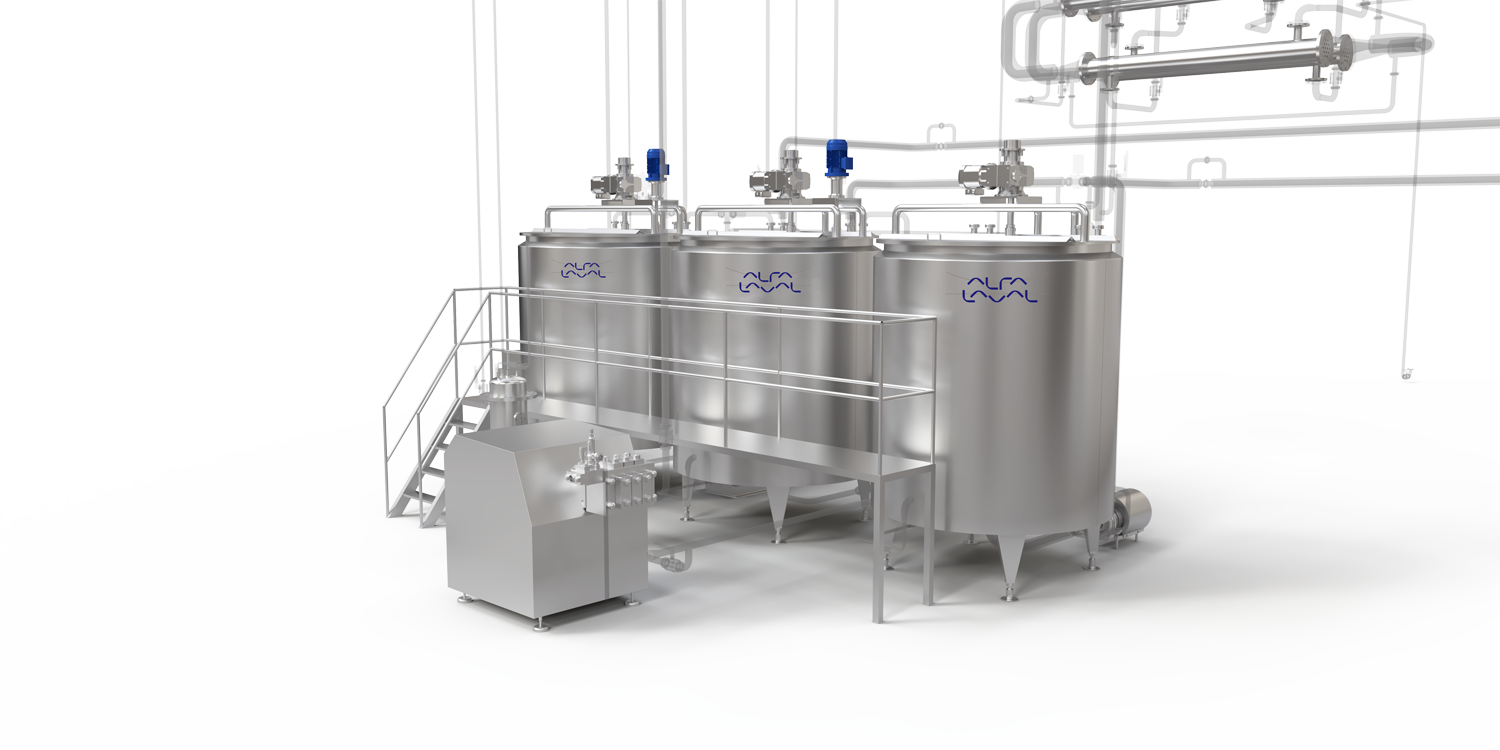

Pombi inotamisa oiri, mafuta kana mafuta akasanganiswa kubva mumatangi ekuchengetera kuburikidza nesefa kuenda kuhuremu system.Kuti uwane huremu hwakakodzera hwemafuta, tangi iyi inoiswa pamusoro pemasero ekutakura.Mafuta anosanganiswa anosanganiswa maererano nekamukira.

Kugadzirira emulsifier kunoitwa nekusanganisa mafuta ne emulsifier.Kana oiri yangosvika patembiricha ingangoita 70°C, maemulsifiers akadai selecithin, monoglycerides uye diglycerides, kazhinji ari muhupfu, anowedzerwa nemaoko mutangi reemulsifier.Zvimwe zvinhu zvinonyungudika nemafuta zvakaita sekupenda uye kuravira zvinogona kuwedzerwa.

Chikamu chemvura mukugadzirwa kwemajarini

Insulated matangi anopihwa kugadzirwa kwechikamu chemvura.Flow meter inodhaisa mvura mutangi umo inodziiswa kusvika kune tembiricha inodarika 45ºC.Dry ingredients semunyu, citric acid, hydrocolloids kana skimmed mukaka poda inogona kuwedzerwa mutangi uchishandisa midziyo yakakosha senge poda funnel mixer.

Emulsion kugadzirira mukugadzirwa kwemajarini

Iyo emulsion inogadzirwa nedosing mafuta nemafuta ane emulsifier musanganiswa uye chikamu chemvura mune yakataurwa.Kusanganiswa kwechikamu chemafuta uye chikamu chemvura chinoitika mu emulsion tank.Pano, zvimwe zvinongedzo, senge flavour, zvinonhuwira uye ruvara, zvinogona kuwedzerwa nemaoko.Pombi inotamisa emulsion inoguma kune tangi rekudya.

Midziyo yakakosha, senge yakakwira shear musanganiswa, inogona kushandiswa padanho rino rekuita kuti emulsion ive yakanaka kwazvo, yakamanikana uye yakasimba, uye kuve nechokwadi chekubatana kwakanaka pakati pechikamu chemafuta uye chikamu chemvura.Iyo inoguma yakanaka emulsion ichagadzira margarine yemhando yepamusoro inoratidza kunaka kwepurasitiki, kusimba uye chimiro.

Pombi inobva yaendesa emulsion kunzvimbo ye pasteurization.

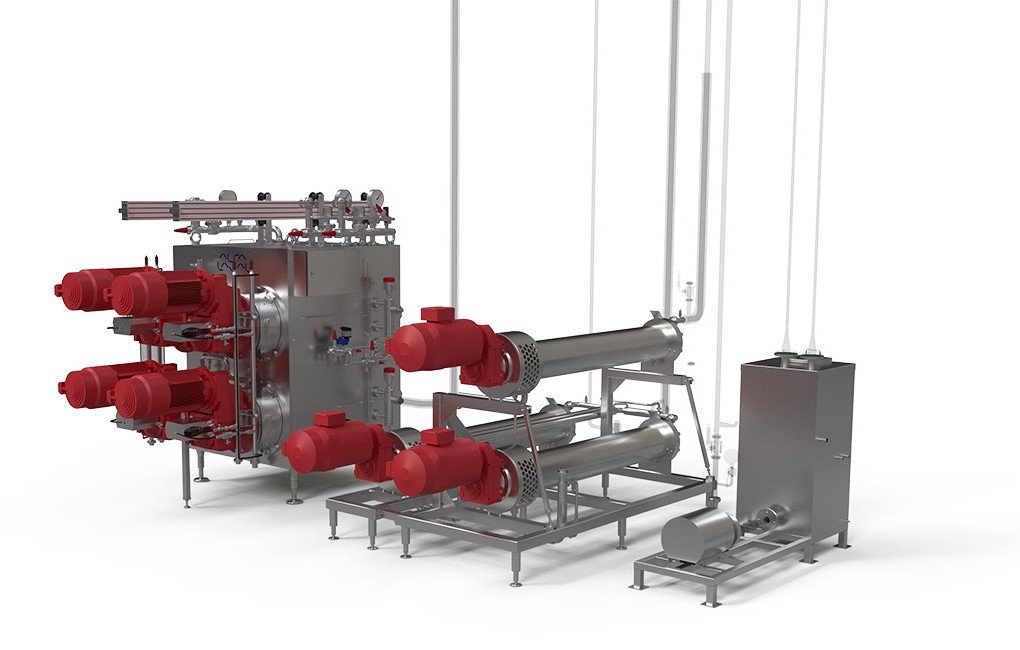

Crystallization mukugadzirwa kwemajarini

Pombi yepamusoro-soro inotamisa emulsion kune yakakwirira-kudzvanywa kwepamusoro-soro kupisa exchanger (SSHE), iyo inogadziriswa maererano nekuyerera kweyero uye recipe.Panogona kunge paine machubhu ekutonhodza akasiyana ehukuru hwakasiyana uye nzvimbo dzekutonhodza dzakasiyana.Silinda yega yega ine yakazvimirira yekutonhodza sisitimu umo refrigerant (kazhinji ammonia R717 kana Freon) inobaiwa zvakananga.Mapombi echigadzirwa anobatanidza silinda imwe neimwe kune imwe.Tembiricha sensors pane imwe neimwe inobuda inovimbisa kutonhora kwakaringana.Iyo yakanyanya kudzvanywa chiyero ndeye 120 bar.

Zvichienderana neresipi uye kushandiswa, emulsion ingangoda kupfuura imwe kana kupfuura pini yevashandi vepini isati yarongedza.Pini yevashandi mayuniti anovimbisa iyo chaiyo yepurasitiki, kuenderana uye chimiro chechigadzirwa.Kana zvichidikanwa, Alfa Laval inogona kupa chubhu yekuzorora;zvisinei, vazhinji vatengesi vepacking machine vanopa imwe.

Kuenderera mberi rework unit

Iyo inoenderera mberi rework unit yakagadzirirwa kunyungudusazve zvese zvakawandisa chigadzirwa izvo zvakapfuura muchina wekurongedza kuti udzokorore.Panguva imwecheteyo, inochengeta muchina wekutakura usina chero usingadiwe backpressure.Iyi yakazara sisitimu ine ndiro yekupisa yekutsinhanisa, yakadzikama inotenderedza pombi yemvura, uye hita yemvura.

Nguva yekutumira: Jun-21-2022