Margarine Production Process

Margarine Production Process

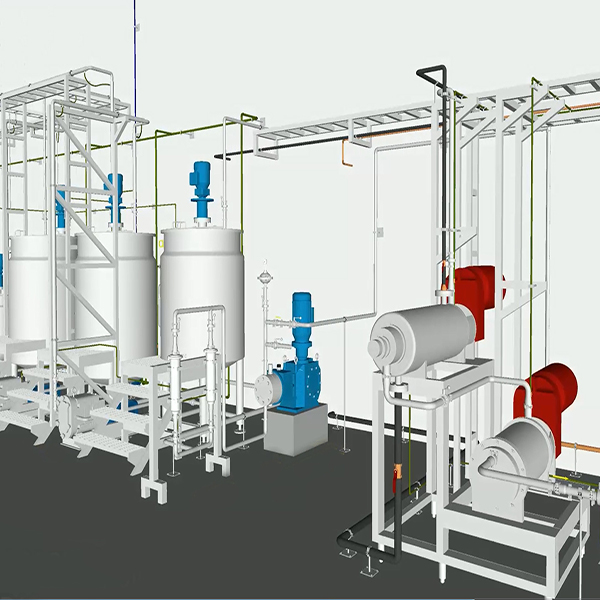

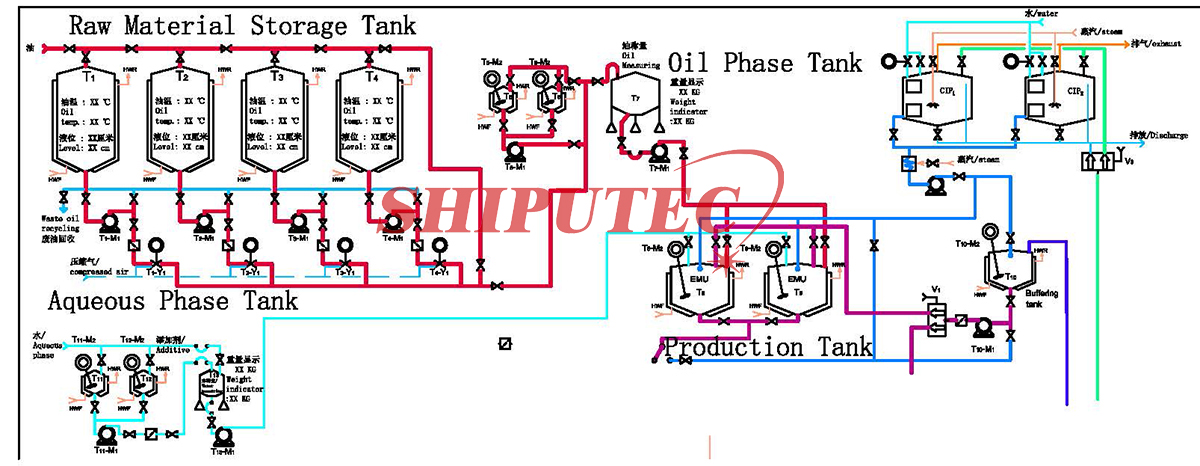

Kugadzirwa kwemajarini kunosanganisira zvikamu zviviri: kugadzirwa kwezvinhu zvakasvibirira uye kutonhora uye purasitiki. Midziyo mikuru inosanganisira matangi ekugadzirira, HP pombi, vhoti (yakaraswa pamusoro pekushisa exchanger), pini rotor muchina, firiji unit, margarine yekuzadza muchina uye nezvimwe.

Iyo yekutanga maitiro musanganiswa wechikamu chemafuta uye chikamu chemvura, kuyerwa uye musanganiswa emulsification yechikamu chemafuta uye chikamu chemvura, kuitira kugadzirira chikafu chekupedzisira. Iyo yekupedzisira maitiro ndeye kuenderera kutonhora kweplasticizing uye chigadzirwa kurongedza.

Iyo mbishi gadziriro yekugadzira margarine inoratidzwa muMufananidzo 1:

- 1.Mukaka wakaviriswa

Vamwe margarine formula kuwedzera mukaka, uye mukaka pashure lactic asidhi mabhakitiriya kuviriswa anogona kubereka zvakafanana kuravidza dzinongoitika ruomba, saka fekitari kuti yakaviriswa mukaka nemvura zvakasanganiswa.

- 2.Kusanganiswa kwemvura

Mvura uye mvura-inonyungudika yekuwedzera mune fomula yemajarini, yakadai semukaka wakaviriswa, munyu, kuchengetedza, nezvimwewo, inowedzerwa kuchikamu chemvura kusanganiswa uye tangi yemita muchikamu chakatemerwa kumutsa nekusanganisa, kuitira kuti chikamu chemvura. zvikamu zvinonyungudutswa kuita yunifomu mhinduro.

- 3.Mafuta chikamu kusanganisa

Oiri yakasvibira yezvakasiyana-siyana zvinotanga kusanganiswa mutangi rekusanganisa mafuta zvichienderana nechiyero chakatarwa, uyezve mafuta-anonyungudika ekuwedzera, senge emulsifier, antioxidant, mafuta-soluble pigment, oiri-soluble cellulose, nezvimwewo, inowedzerwa chikamu chemafuta zvichienderana nechiyero, chakasanganiswa ne metering tank, uye yakasimudzwa kuti iite yunifomu yemafuta chikamu.

- 4.The emulsion

Chinangwa che emulsification yemajarini ndechekuita chikamu chemvura chakaenzana uye chakapararira muchikamu chemafuta, uye dhigirii rekupararira kwechikamu chemvura chine simba guru pamhando yechigadzirwa. Nekuti kunhuhwirira kwemargarine kwakabatana zvakanyanya nehukuru hwechikamu chemvura, kupararira kwehutachiona kunoitwa muchikamu chemvura, saizi yehutachiona hwese ndeye 1-5 microns, saka madonhwe emvura mu10-20. ma microns kana madiki madiki anogona kudzikamisa kupararira kwebhakitiriya, saka kupararira kwechikamu chemvura kwakanyanyisa, zvikamu zvemvura zvakadikidiki zvichaita kuti margarine irasikirwe nekunaka; Kuparadzira hakuna kukwana, chikamu chemvura chakakura kwazvo, chichaita kuti margarine ishatise metamorphism. Hukama huri pakati pechiyero cheaqueous phase dispersion mumajarini uye hunhu hwechigadzirwa hunenge hunotevera:

| 水滴直径 Mvura inodonha dimension (微米 micrometer) | 人造奶油性质 (Taste of Margarine) |

| isingasviki 1 (inenge 80-85% yechikamu chemvura) | Kurema uye kuravira kushoma |

| 30-40 (pasi pe1% yechikamu chemvura) | Kuravira kwakanaka, nyore kusvibiswa |

| 1-5 (inenge 95% yechikamu chemvura) | Kuravira kwakanaka, kwete nyore kuodzwa |

| 5-10 (inenge 4% yechikamu chemvura) | |

| 10-20 (inenge 1% yechikamu chemvura) |

Zvinogona kuonekwa kuti emulsification kushanda kunofanira kusvika kune imwe nhanho yekuparadzira zvinodiwa.

Chinangwa chekusanganisa chikamu chemvura uye chikamu chemafuta zvakasiyana uye zvakaenzana nechikamu chekutanga ndechekuita kuti yunifomu ienderane ye emulsion yose mushure me emulsification uye kusanganiswa kwemafuta nemvura zvikamu zviviri. Emulsification kusanganisa ndere, dambudziko rekushanda i50-60 madhigirii, chikamu chemvura chinowedzerwa kune yakayerwa mafuta chikamu, mune mechaniki inosimudzira kana pombi kutenderera ichikurudzira, ndiyo chikamu chemvura chakaparadzirwa zvizere muchikamu chemafuta, kuumbwa kwelatex. Asi rudzi urwu rwe latex liquid haina kugadzikana, mira kubvongodza inogona kunge iri panzvimbo yekutamba mafuta uye mvura yekuparadzanisa chiitiko.

Mushure mokunge emulsion yakavhenganiswa yaendeswa, kutonhora uye kushandiswa kwepurasitiki kunoitwa kusvikira chigadzirwa chacho chaiswa.

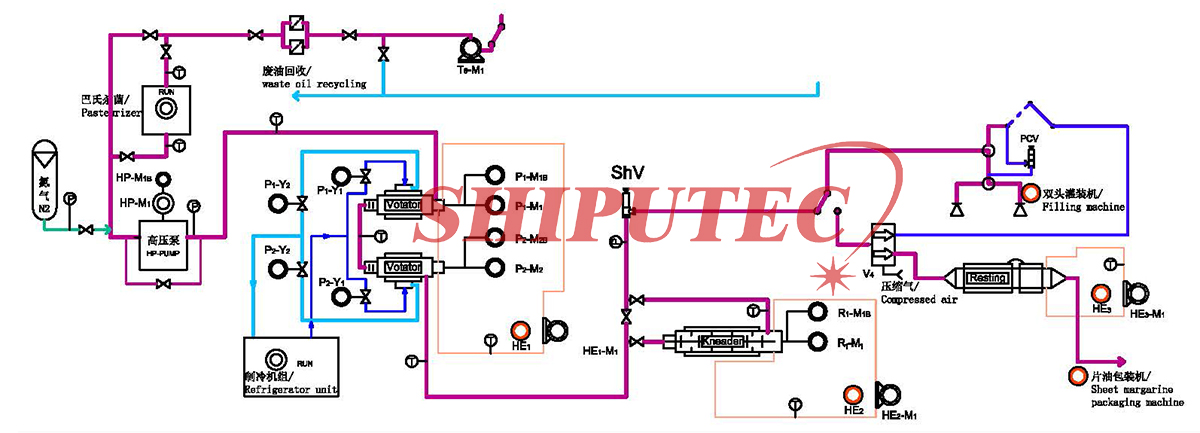

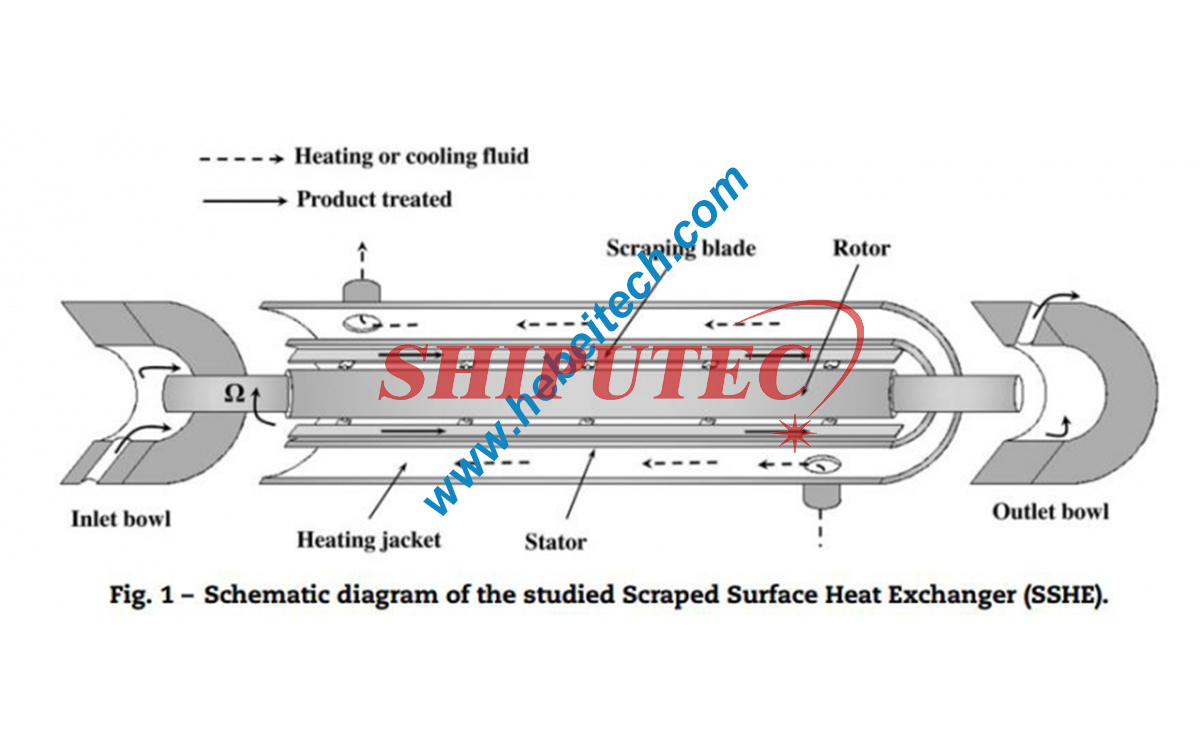

Iyo emulsion inofanirwa kutonhodzwa uye kuiswa mupurasitiki kuti ibudise inoshanduka margarine chigadzirwa. Parizvino, inonyanya kushandisa yakavharwa inoramba ichidzima plasticizing mudziyo, unosanganisira vhoti kana inonzi scraped pamusoro kupisa exchanger (unit A), pini rotor muchina kana kukanyira muchina (unit C) uye resting chubhu (unit B). Iyo tekinoroji maitiro inoratidzwa muMufananidzo 2:

Iyi seti yemidziyo ine zvinotevera maitiro:

1. High pressure airtight inoenderera mberi kushanda

Iyo premixed emulsion inodyiswa muhumburumbira hwekudzima nepombi yepamusoro yekuvhota. Kudzvinyirirwa kwakanyanya kunogona kukurira kupikisa mukati mechikamu chose, mukuwedzera kune yakanyanya kudzvanywa kushanda kunogona kuita kuti chigadzirwa chitete uye chakatsetseka. Kuvharwa kushanda kunogona kudzivirira mhepo nemhepo nekuda kwekudzima uye condensation yemvura yakasanganiswa ne emulsion, iva nechokwadi chezvinodiwa zvehutano hwechigadzirwa, kuderedza kurasikirwa kwefiriji.

2. Kudzima uye emulsification

Iyo emulsion inodzimwa neammonia kana Freon muvhoti kuti itonhodze emulsion nekukurumidza, kuitira kuti kugadzirwa kwediki crystalline particles, kazhinji 1-5 microns, kuitira kuti kuravira kuve kwakapfava. Uye zvakare, iyo scraper pane inotenderera shaft muvhoti yakanyatsobatana nemukati memadziro ecylinder, saka iyo scraper iri kushanda haigone kungoramba ichikwenya kristalllization inonamatira kumadziro emukati, asiwo kuita kuti emulsion iparadzirwe kusangana ne. emulsification zvinodiwa zvezwi.

3. Kukanyira nekubvisa mutsindo (pini rotor muchina)

Kunyangwe iyo emulsion yakatonhodzwa nemuvhoti yatanga kuburitsa crystallization, ichiri kuda kukura nekufamba kwenguva. Kana iyo emulsion ichibvumidzwa kupenya pakuzorora, network yeakasimba lipid crystals inoumba. Mhedzisiro ndeyokuti emulsion yakanyoroveswa ichaita misa yakaoma kwazvo isina plastiki. Naizvozvo, kuti uwane zvigadzirwa zvemajarini zvine mamwe mapurasitiki, iyo network dhizaini inofanirwa kuputswa nema mechanical nzira musati emulsion inogadzira iyo yakazara network chimiro, kuitira kuti iwane mhedzisiro yekudzikisa thickening. Kneading uye de-thickening inonyanya kuitwa mupini rotor muchina.

Yuniti A (vhoti) inonyatso scraper yekutonhodza mudziyo. Iyo emulsion inofambiswa mukati yakavharwa unit A (vhota) nepamusoro-kudzvanywa pombi. Izvo zvinhu zvinopfuura nemugero pakati pehumburumbira inotonhorera uye shaft inotenderera, uye tembiricha yemidziyo inodonha nekukurumidza nekudzima kwepakati inotonhorera. Mitsara miviri ye scrapers yakarongedzwa pamusoro pepamusoro pe shaft. Makristasi akaumbwa pamusoro pemukati wemuvhoti anokweshwa nechekure-speed rotating scraper kuti agare afumura nzvimbo itsva inotonhorera uye kuchengetedza kupisa kwakanyanya. Iyo emulsion inogona kuparadzirwa pasi pechiito che scraper. Kana zvinhu zvichipfuura nechikamu A (vhota), tembiricha inodonha kusvika 10-20 madhigirii, iyo yakaderera pane yekunyungudika kwemafuta. Kunyange zvazvo oiri inotanga kupenya, haisati yaumba chimiro chakasimba. Panguva ino, emulsion iri mumamiriro ekutonhodza uye imvura yakakora.

Axis yekutenderera yeyuniti A (vhoti) haina mhango. Munguva yekushanda, mvura inopisa ye50-60 madhigirii inodururwa pakati peiyo axis inotenderera kudzivirira crystallization yakasungwa uye kuporeswa paaxis uye kukonzera kuvharika.

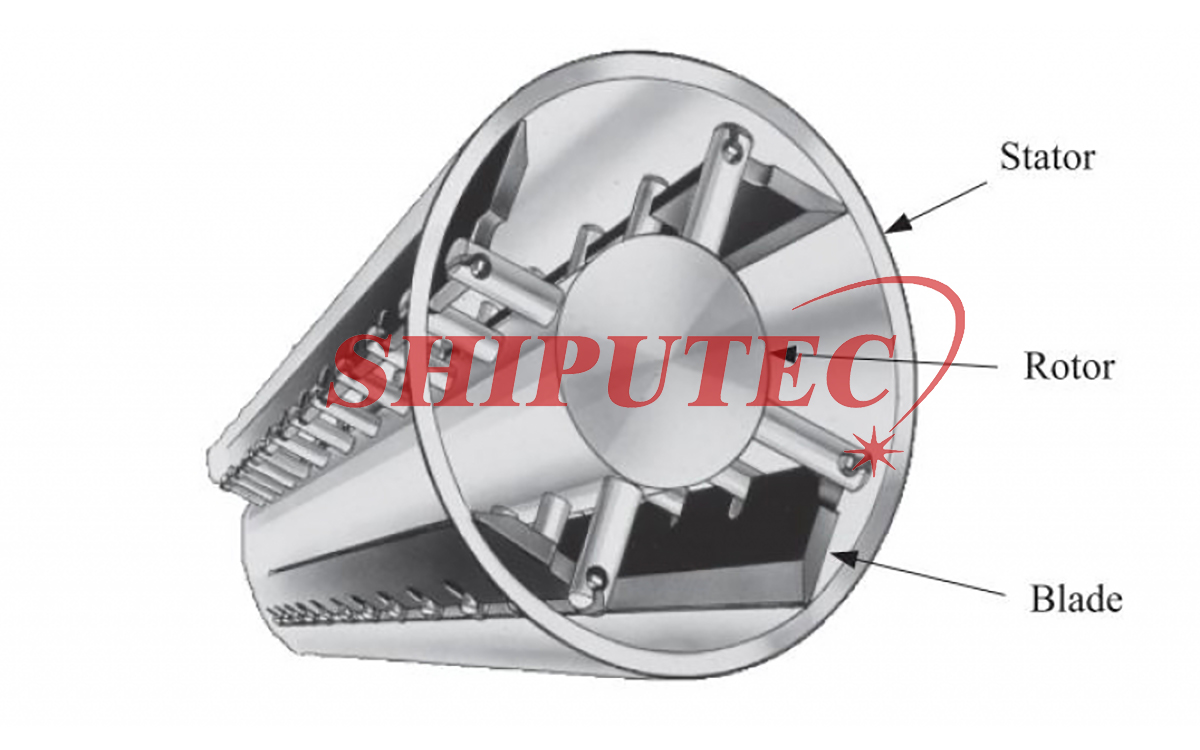

Yuniti C (pini rotor muchina) inokanya uye kubvisa-yakakora mudziyo, sezvakaratidzwa mumufananidzo uri pamusoro. Mitsara miviri yemabhoti esimbi akaiswa pane inotenderera shaft, uye mutsara wesimbi yakagadzika mabhaudhi akaiswa pamadziro emukati ehumburumbira, ayo anozununguka nesimbi mabhaudhi pane shaft uye haabatane. Kana shaft ichitenderera nekumhanya kukuru, mabhoti esimbi pane shaft anopfuudza gaka resimbi yakagadzika mabhoti, uye zvinhu zvacho zvinokanyiwa zvizere. Pasi pechiito ichi, inogona kukurudzira kukura kwekristaro, kuparadza kristaro network chimiro, kuumba discontinuous makristasi, kuderedza kuwirirana, uye kuwedzera plasticity.

Unit C (pini rotor muchina) inongoridza yakasimba kukanya mhedzisiro pahusiku hunotonhora zvakanyanya, saka inongoda kuchengetedza kupisa uye haidi kutonhora. Sezvo kupisa kwekristalllization kunoburitswa (inenge 50KCAL/KG), uye kupisa kunoitwa nekukanyira kukweshera, tembiricha yekuyerera yeunit C (pin rotor macjhine) yakakwirira kupfuura iyo yekushisa kwekudya. Panguva ino, iyo crystallization inenge 70% yakakwana, asi ichiri nyoro. Chigadzirwa chekupedzisira chinoburitswa kuburikidza neiyo extrusion vharafu, uye ichave yakaoma mushure meimwe nguva.

Mushure mekunge margarine yatumirwa kubva kuC unit (pini rotor muchina), inoda kupisa inobatwa pane imwe tembiricha. Kazhinji, chigadzirwa chinoiswa pakupisa kwe10 degrees pazasi pekunyungudika kwemaawa anopfuura makumi mana nemasere. Mushonga uyu unonzi kuibva. Chigadzirwa chakabikwa chinogona kutumirwa zvakananga kune chikafu chekugadzira chikafu kuti chishandiswe.